Plastic Granules: The Foundation of High-Quality Plastic Products

Introduction Plastic granules are the raw material used in the manufacturing of various plastic products. These small, pellet-like materials are made from different types of polymers, each with unique properties that determine their suitability for specific applications. Industries such as packaging, automotive, construction, and consumer goods rely on plastic granules to produce durable, lightweight, and cost-effective plastic products.

Types of Plastic Granules

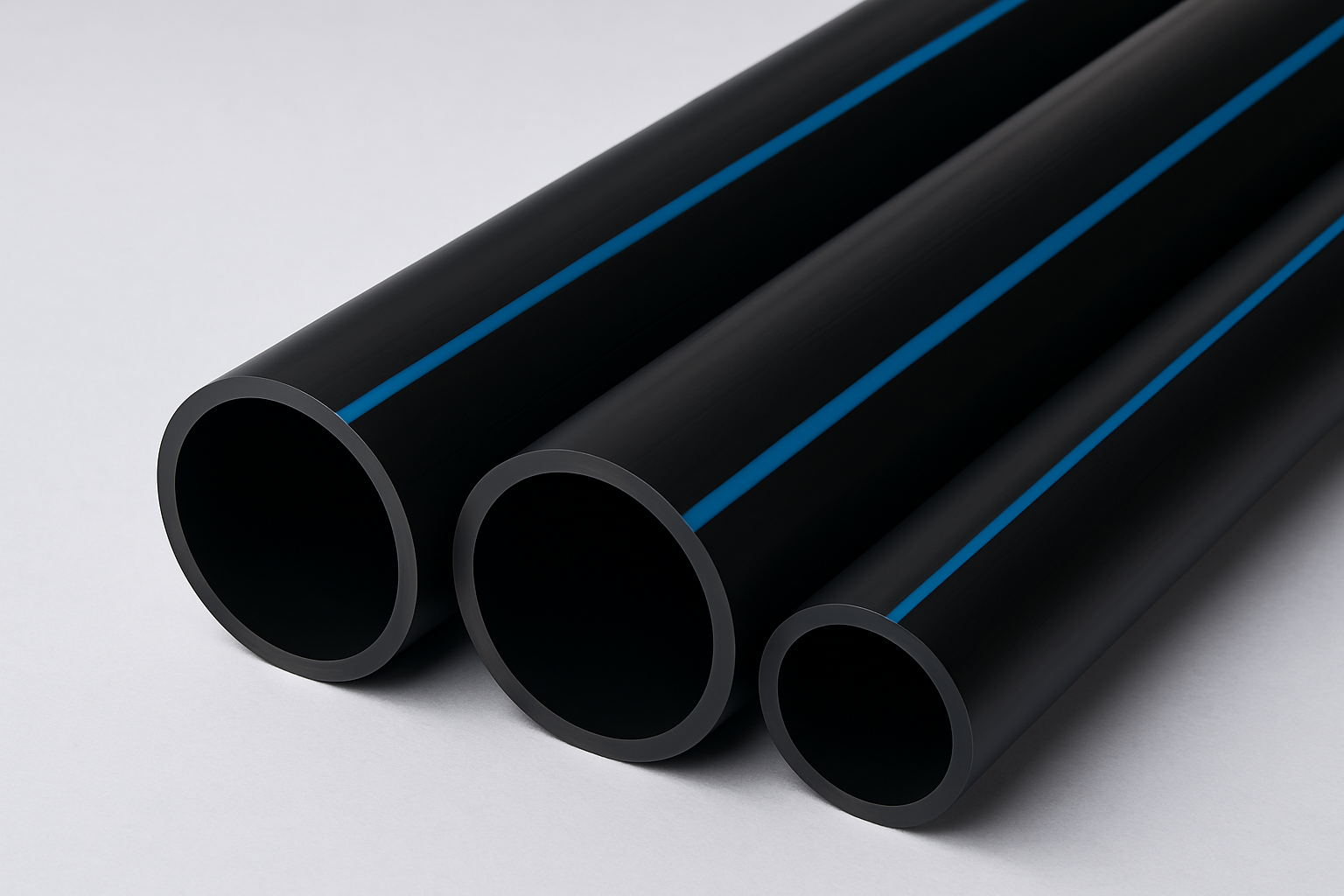

- Polyethylene (PE) Granules

- High-Density Polyethylene (HDPE): Used for pipes, containers, and household products.

- Low-Density Polyethylene (LDPE): Commonly used for films, plastic bags, and flexible packaging.

- Polypropylene (PP) Granules

- Ideal for packaging, automotive parts, and household applications due to their high strength and heat resistance.

- Polyvinyl Chloride (PVC) Granules

- Used for pipes, window profiles, cables, and flooring.

- Polystyrene (PS) Granules

- General-Purpose Polystyrene (GPPS): Used in disposable containers and transparent packaging.

- High-Impact Polystyrene (HIPS): Used in toys, appliances, and electronics.

- Acrylonitrile Butadiene Styrene (ABS) Granules

- Commonly used in automotive parts, electronics, and household appliances.

- Polyethylene Terephthalate (PET) Granules

- Widely used for making plastic bottles, food containers, and textile fibers.

Applications of Plastic Granules

- Packaging Industry: Used to produce plastic bags, bottles, containers, and flexible films.

- Automotive Industry: Helps manufacture lightweight and durable vehicle components.

- Construction Industry: Used in the production of pipes, fittings, roofing sheets, and insulation materials.

- Consumer Goods: Found in household appliances, furniture, toys, and kitchenware.

- Medical Industry: Used in the production of medical-grade plastic products like syringes and tubing.

Advantages of Plastic Granules

- Versatility: Can be molded into various shapes and sizes for different applications.

- Durability: Resistant to wear, impact, and environmental factors.

- Cost-Effective: Provides a cheaper alternative to traditional materials like metal and glass.

- Recyclability: Many plastic granules are recyclable, reducing environmental impact.

- Lightweight: Makes products easier to transport and handle.

Conclusion Plastic granules play a vital role in modern manufacturing, offering endless possibilities for innovation and production efficiency. Whether for industrial, commercial, or consumer applications, high-quality plastic granules ensure the durability and performance of plastic products.

For more information on our range of plastic granules, contact us today!